Type C Looseness Vibration

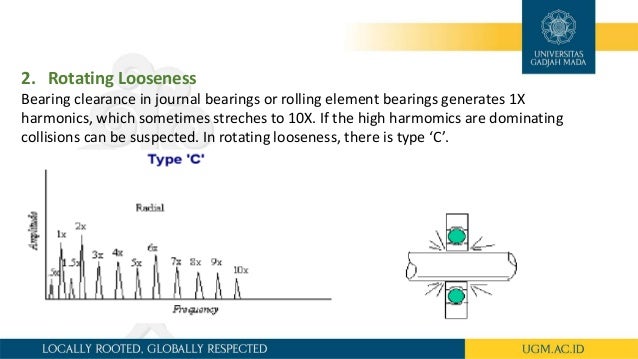

How can the answer be improved? Looseness Looseness - Not a vibration source but an amplifier. That means that when a component is loose, whatever forces are present will be able to move the affected components much more easily. If there are little or no forces present, however, vibration may only increase a very small amount. MECHANICAL LOOSENESS Note Raised Noise Floor Indicating Looseness Mechanical Looseness is indicated by either Type A, B or C vibration spectra.

Mechanical looseness, or the improper fit between component parts, is generally characterized by a long string of rotating frequency harmonics or 1/2 rotating frequency harmonics at abnormally high amplitudes.It’s important to note that these harmonics may be sporadic.

An increase or change in the vibration of machinery is normally an indication that something is wrong. Anyone mechanically minded knows an unusual vibration is telling them to carry out maintenance before things get worse. Vibration analysis is the science of using vibrations to gain deeper insights into the condition of machinery. When vibration signals are understood, it is like looking inside a moving machine and seeing how everything is performing.

The condition of balance, lubrication, bearings and gears can all be uniquely identified from a single vibration signature.Because these diagnostics are carried out while machinery is operating, there is no need for any downtime while diagnostics are being carried out. A fault can be identified, spare parts ordered and the maintenance work scheduled in a way that minimizes disruption to operations. Vibration analysis can prevent catastrophic failure and lessen the chances of secondary damage, excessive down-time, safety incidents, a higher cost of repair and lost production. In this introduction to vibration analysis, I’ll explain how it works and what information it can give you about the condition of machinery. Measuring VibrationTypically, vibration is measured using an accelerometer, although it could also be measured as a velocity or displacement signal. The simplest way to measure vibration would be by measuring displacement. This can provide a useful intuitive understanding of vibration signals.

For example, consider measuring the radial displacement of a poorly aligned shaft using a dial indicator. As the shaft rotates at a constant speed, the dial indicator will record a sinusoidal displacement. This sine wave will have a frequency equal to the speed of rotation (1 Hz = 1 cycle per second). The waveform will have an amplitude that is the maximum displacement from the nominal positon for a perfectly aligned shaft. The final property of the waveform, the phase shift, indicates where in the cycle it starts.

The phase shift is only relevant when comparing two vibration sources. I’ll explain more about this later.

When a poorly aligned shaft is rotated, the resulting axial displacement follows a sine wave.Acceleration is the rate of change in velocity, and velocity is the rate of change in displacement. It would therefore be possible to differentiate the displacement to obtain the velocity and again to give acceleration. Since the derivative of sinθ is cos θ and the derivative of cos θ is –sin θ, all of these signals will be sinusoidal but with phase shifts between them.Using a dial indicator in contact with a shaft would be impractical unless the shaft was turning very slowly. It is, however, sometimes practical to make displacement measurements using eddy current proximity sensors, such as for detecting vibration in a machine tool spindle or shaft within journal bearings. The best signal to use depends on the frequencies of the vibrations.

At low frequencies below 10 Hz, displacement may be best. Above this velocity, it starts to become more useful and beyond 2 kHz acceleration is best. Typically, it is acceleration that is measured, using an accelerometer, and the signal is then integrated to give a velocity signal.

As I will show later, the frequency depends on both the running speed of shafts in rotating machinery and the type of fault. Balance, misalignment and looseness have frequencies either at the running speed or a few multiples of it.

For typical machinery, this makes velocity the best signal to detect them. Bearings produce vibrations at much higher frequencies, which can be seen more clearly in acceleration signals.Accelerometers are normally located on the outside of a machine.

Type C Looseness Vibration Meaning

Sometimes they are attached using a magnet, and sometimes a handheld probe is simply held against the surface. Generally, magnetic attachment produces a cleaner signal with better accuracy and a wider frequency range. A hand-held vibration meter. The accelerometer can be magnetically attached to machinery. (Image curtesy of Extech Instruments.)When locating sensors, both position and direction are important.

Vibrations will generally have the greatest amplitude closest to their source, especially for high frequencies. Positioning the sensor over a number of possible sources can, therefore, be a good way to find the fault. An example might be taking a reading over each bearing along a shaft. The direction of vibrations can also provide useful diagnostic information. For example, certain bearing faults, as well as angular misalignment of shafts, produces axial motion.

Other faults, such as a shaft that is poorly balanced, will produce radial motion. Accelerometers typically measure motion in the direction perpendicular to the surface onto which they are attached, although it is possible to mount them at other angles via brackets. Vibrations in rotating machinery may be radial or axial.

LucentAgereLucentLucentLucentAgereLucentLucentLucentAgereLucentLucentFor a list of all currently documented Lucent chipsets with specifications, see.For a list of all currently documented Philips chipsets with specifications, see.These cards were extremely popular in the early 2000s before the 802.11g standard was finalized.This was the card (authored by ) was written for. Proxim orinoco pc card.

Identifying Faults Within Complex SignalsA real vibration measurement is very unlikely to be a simple sine wave. In real machinery, many sources of vibration combine to produce complex vibration signatures. Spectrum analysis can be used to isolate individual sources of vibration, allowing faults to be diagnosed. It separates out waveforms based on their frequency. Most vibration analysis is carried out in the frequency domain, looking for changes in the condition of machinery or sources of excessive vibration.

Changes are indicated by a change in the amplitude of vibration at a particular frequency or new frequencies appearing. The frequency of high-amplitude vibrations, as well as their position and direction, can usually identify the cause of a fault in a machine. Analysis involves looking for peaks in the frequency domain plot. This will be easier to understand through an example.We will consider a simple vibration signature for a machine with just three sources of vibration (A, B and C). Each source produces a simple sine wave that can be characterized by its amplitude, frequency and phase shift. What we actually see in the readout from the accelerometer is the sum of these three waveforms.

The vibration produced by each source, as well as the combined vibration, is shown below. It is clear that the combined vibration, which the sensor will show us, seems to be chaotic and is very difficult to draw any conclusions from. Combined effect of three sinusoidal vibrations.If we know the three simple waveforms (A, B and C), then it’s easy to add these together to get the combined vibration signal. Doing this the other way around is not so easy. Have a look at the vibration signal above and consider how you might identify that this is made up of the three simple sine waves that we know it to be composed of. Fourier analysis provides the mathematical tools to solve this inverse problem. In particular, Fast Fourier Transform (FFT) algorithms are employed by vibration analysis software to decompose a complex vibration signal, identifying the underlying waveforms.

These methods may also be referred to as spectrum analysis, with results summarized in a spectral plot. This is a plot of frequency against amplitude with peaks indicating the frequency and amplitude of significant underlying waveforms. Spectral plot showing the frequency and amplitude of the main sources of vibration.When viewing the results of a spectrum analysis for rotating machinery, it is convenient to present frequencies as multiples of the shaft running speed (1X). Initial diagnosis can then be carried out based on frequency and direction by applying some simple mechanics based rules:. 1X frequency vibration may indicate unbalance or angular misalignment. A machine in good condition will generally have this frequency at a reasonably low amplitude, but all the other frequencies will be even lower. Resonance will cause this spike to increase in amplitude and possibly also broaden at its base.

Angular misalignment between shafts generally produces axial vibrations at the running speed since this creates relative motion between the shafts, in the axial direction, with the distance peaking once per revolution. Parallel misalignment produces radial vibrations that may be at the running speed or a multiple of it depending on the coupling used. Integer multiples of 1X (e.g. 2X or 3X) may indicate parallel misalignment, loose bearings, pumps or fans running away from best efficiency points, damaged gears etc.

For example, a spike at 22X close to a 22 tooth gear, would point towards that gear as a source. Very high frequency shock pulses, sometimes at low amplitude, may indicate a defect in a bearing case. This will produce a shockwave each time one of the rollers passes the defect. The frequency will depend on the running speed, the number of rollers and the time it takes each roller to precess around the casing. This is almost never at an exact multiple of running speed. The high frequency and initially low amplitude makes early detection of these bearing faults difficult using standard spectral analysis. Methods to remove low frequency, high amplitude, vibrations so that these effects can be observed are required for this.