Software For Design Of Heat Exchanger

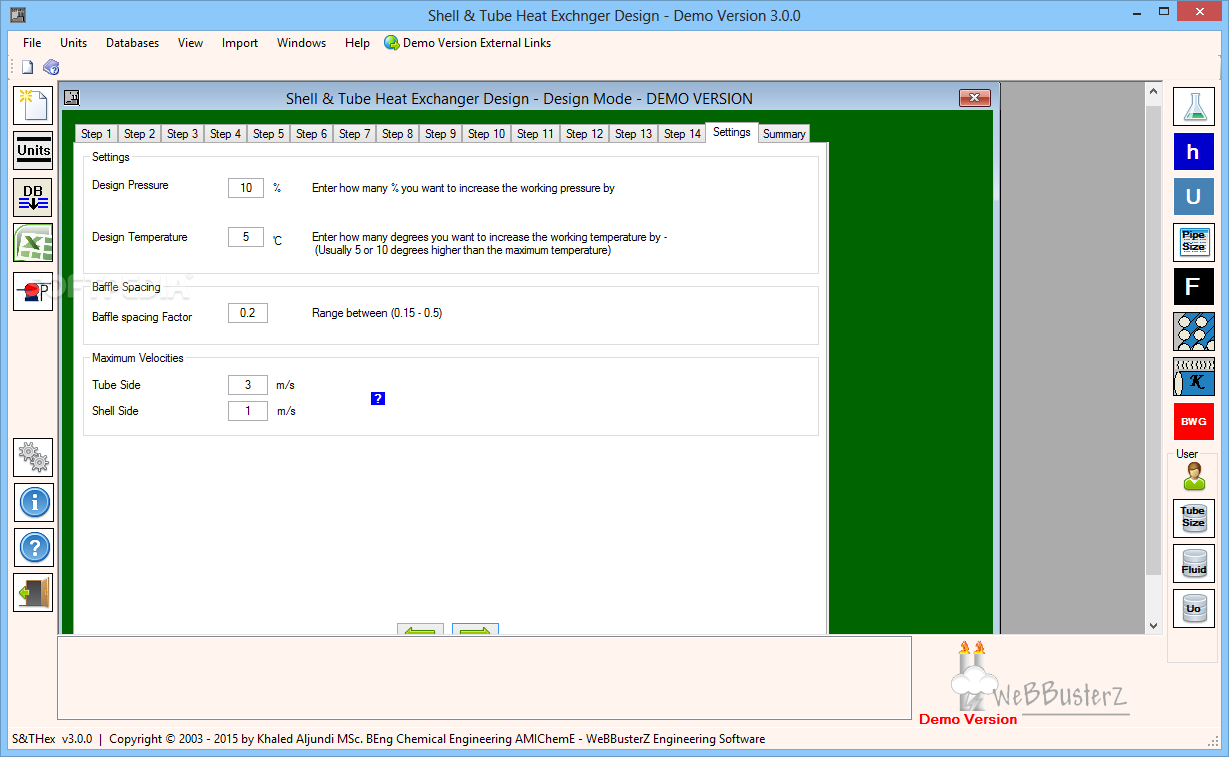

New in Shell and Tube Heat Exchanger Design 3.2.0.0: Migrated to Microsoft.net Framework 4.5 Improve loading of default and custom software settings for design mode. Shell and tube heat exchanger design (S&THex) software able to perform thermal process design calculations and generate engineering datasheet.

- Software For Design Of Heat Exchanger Systems

- Heat Exchanger Software For Mechanical Design

- Heat Exchanger Design Calculations

There are many widely used in the process industry. They are used for cooling down or heating up any process fluids, for example - oil, natural gas, coolant fluids, water, steam etc. Out of all these types are most popular and widely used, due to their. Heat exchanger design calculationsNormally, a process design engineer must create the process, with details like - service, heat duty, utility, allowable pressure drop on shell & tube sides, operating and design T & P conditions. These parameters are determined based on some calculations.

Here are some to help you with those calculations. Heat Exchanger Design Software ToolsBut most process engineers commonly rely on process simulation software to quickly perform these heat exchanger design calculations.

Then let's look at some commonly used heat exchanger design software tools which can help you. HTRI's Xchanger SuiteThe core business of is focused on heat exchanger design software tools.

Their core product is a very popular package for heat exchanger design. Is their heat exchanger modeling tool which can be used within the wider Aspen HYSYS and Aspen Plus platforms to produce the most optimal designs at the right economics.Some of their important features are -. Comprehensive set of rigorous heat exchanger (HX) models.

Fully incorporate heat exchanger designs within Aspen HYSYS and Aspen Plus. Comprehensive, up to date documentation.

Design all major heat exchanger types, including shell and tube, fired heater, plate, plate-fin, coil-wound, air-cooled and more. Improve mechanical shell-and-tube exchanger design quality. Database with 37,000 components, 127 property packages and 5M+ data points and interaction parameters.

State-of-the-art activity coefficient models and equations of state.COMPRESS by Codewareis a pressure vessel design software by Codeware. COMPRESS ensures that your pressure vessel design is in accordance with ASME VIII standards.

The heat exchanger option in COMPRESS helps you with heat exchanger design calculations based on ASME UHX and TEMA mechanical design guidelines.Important features are.

This figure shows you general step-by-step method of design of shell and tube heat exchanger. Design of shell and tube heat exchangerThis is the explanation:. Define the duty (Q) from mass flow rate, inlet temperature, outlet temperature, and heat capacity. I usually calculate for both shell side and tube side just to ensure that the duty is similar. If you have heat capacity properties in inlet side and outlet side, I recommend to use average value. Sometimes, in sizing we have to add contingency, for example 10%. So the calculated duty shall be multiplied by 110%.

Collect physical properties. It is very clear step. Use average value for all properties.

Select trial value of overall heat transfer coefficient (U guess). There is particular graph to estimate overall heat transfer coefficient. The graph is a function of process fluid heat transfer coefficient and service fluid heat transfer coefficient. Calculate mean temperature difference (delta T m). Actually delta T m itself is not sufficient. We have to calculate corrected delta T m which is a function of temperature ratios (R, S) and configuration of shell and tube heat exchanger (number of tube pass, number of shell pass). We will get correction factor (F t) from nomograph.

Corrected is delta T m x F t. Calculate heat transfer area (A). By using equation A = Q/(U x corrected delta T m), you will get estimated heat transfer area.

Decide exchanger layout. Although this step only contains three words, the actual step is so many. I will explain this step in separate section. Calculate individual heat transfer coefficient (shell side and tube side). For shell side, heat transfer coefficient is a function of baffle cut, tube arrangement, Reynold number, and Prandtl number. As for tube side, heat transfer coefficient is a function of L/di, Reynold number, and Prandtl number.

Software For Design Of Heat Exchanger Systems

Calculate overall heat transfer coefficient. In addition of shell side and tube side heat transfer coefficient, you will also need fouling coefficient at shell side and tube side and also thermal conductivity of tube material to calculate overall heat transfer coefficient. Sometimes fouling coefficients are defined by user/contractor. If this data is not available, we need to estimate.

Heat Exchanger Software For Mechanical Design

Check if U guess in step 3 is the same as U calculated in step 8. I think this is the hardest part. In the beginning of design, I think we will get big difference between U guess and U calculated. If that happens, revise U guess and follow the whole step over. U guess is usually in form of range. Be careful to check several data that is provided from nomographs ( we will use many nomographs in design of shell and tube heat exchanger). If you feel satisfied with the results, for example the difference between U guess and U calculated is less than 10%, then follow next step.

Calculate pressure drop at shell side and tube side. Check if calculated pressure drop meets requirement. There are two approach to calculate pressure drop in shell and tube heat exchanger: Kern Method and Bell Method. I usually use those two methods and compare which value is satisfied (I use the highest one). The last step is design optimization. The most optimized one is the one with the smallest area.

Heat Exchanger Design Calculations

But you need to pay attention to shell side and tube side velocity and pressure drop.Reference:Chemical Engineering Design – RK SinnotFeature image from.